Residential Tulip Windows

Residential Conservation

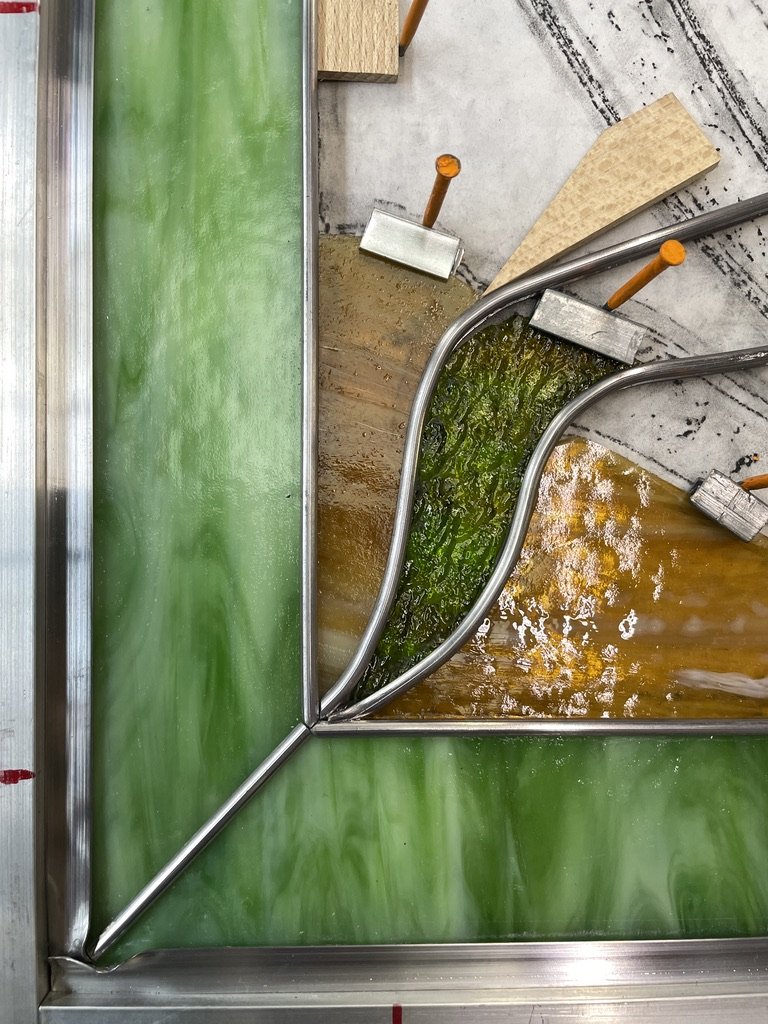

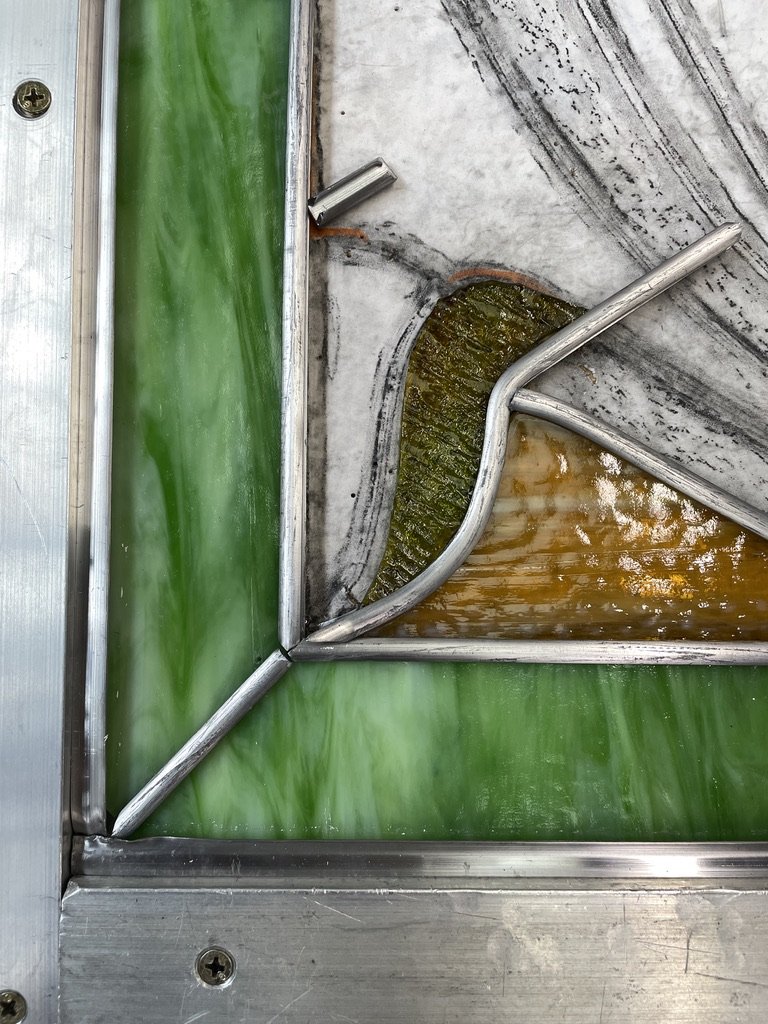

Materials: multicolored glass, 3/8” flat lead and 9/16” round lead cane, 50/50 lead tin solder, linseed oil putty.

These two residential panels were initially thought to be an in situ repair of one piece of glass. But, after our assessment and pointing out to the client that previous contractor’s repairs were insufficient (clear silicone over bowing) and the structural integrity of the panels was compromised (numerous breaks at the solder joints) - the project turned into a complete re-leading project.

This afforded us the opportunity to edge bond multiple pieces and clean the glass. We also worked with the client to arrive at the perfect lead option to balance the glass with the lead lines.

The windows were constructed using all hand-cut glass. The panels were leaded using 3/8" flat lead for the border and 9/16" round lead in the field. Multiple pieces of glass had cracked and required edge-bonding.

All textured glass was positioned on the interior and broken pieces were edge-bonded before glazing. After the leading was complete, each panel was soldered and puttied by hand. Both panels underwent a final clean and polishing before installation at the client's residence. The panels were installed with a putty bevel on the exterior that was then painted.